Why do LED light strips with 5-year warranty require pure gold wire for chip bonding?

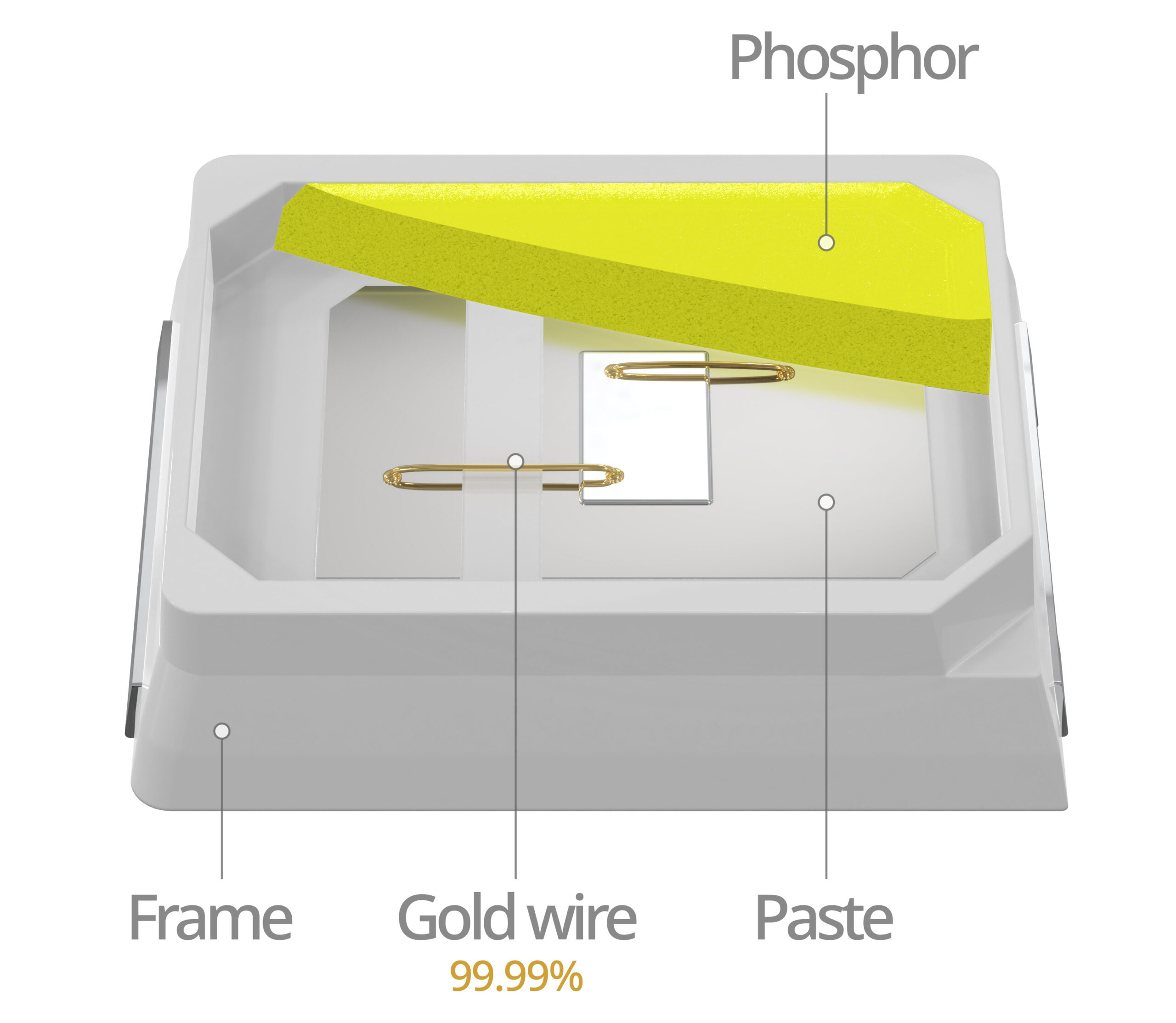

One of the core components in the packaging of LED light chips is the bonding wire. Here is a detailed introduction to the differences and characteristics of three materials: 99.99% pure gold wire, alloy wire, and copper wire:

99.99% Pure Gold Wire

- Characteristics: Pure gold wire is the top choice in high-end LED packaging. It has a purity of 99.99% and exhibits extremely high conductivity and stability.

- Advantages: Pure gold wire excels in electrical connections and offers advantages in stability and reliability. Gold has excellent oxidation resistance, allowing for long-term stable connections and reducing the risk of performance degradation.

- Application Range: Due to the high cost of pure gold wire, it is typically used in high-end LED products, especially those that require long-term warranty.

Alloy Wire

- Characteristics: Alloy wire is an alternative to pure gold wire, composed of a combination of silver monocrystals and other elements.

- Advantages: Alloy wire offers a better cost-performance ratio. Compared to pure gold wire, alloy wire is more affordable while still maintaining good conductivity and welding performance. Although it has lower oxidation resistance than pure gold wire, it still provides satisfactory performance in most applications.

- Application Range: Alloy wire is commonly used in mid-to-high-end LED products to balance performance and cost.

Copper Wire

- Characteristics: Copper wire is the most cost-effective choice among the three materials, costing only a fraction of pure gold wire.

- Advantages: The main advantage of copper wire is its low cost, which can significantly reduce production costs. It is suitable for price-sensitive LED products.

- Disadvantages: However, copper wire is prone to oxidation, which can lead to decreased conductivity and potential performance issues. Additionally, the soldering process for copper wire is relatively less stable, and its physical parameters such as hardness and yield strength are not as good as gold or alloy wire.

- Application Range: Due to its performance limitations, copper wire is generally not recommended for LED products with long-term warranties or high-performance requirements.

When selecting bonding wire materials for LED chip packaging, LED manufacturers consider factors such as product quality, performance requirements, and cost. Pure gold wire offers the best reliability and durability but comes at a higher price. Alloy wire provides a cost-effective alternative, while copper wire offers an economical choice but may sacrifice performance and stability. Based on the intended application and target market segments, LED manufacturers carefully choose the appropriate bonding wire material to strike a balance between performance and cost-effectiveness. Therefore, in the DENO LIGHTING product series, the high-end products with a five-year warranty are all equipped with 99.99% pure gold wire, while the mid-to-high-end products with a three-year warranty use alloy wire.

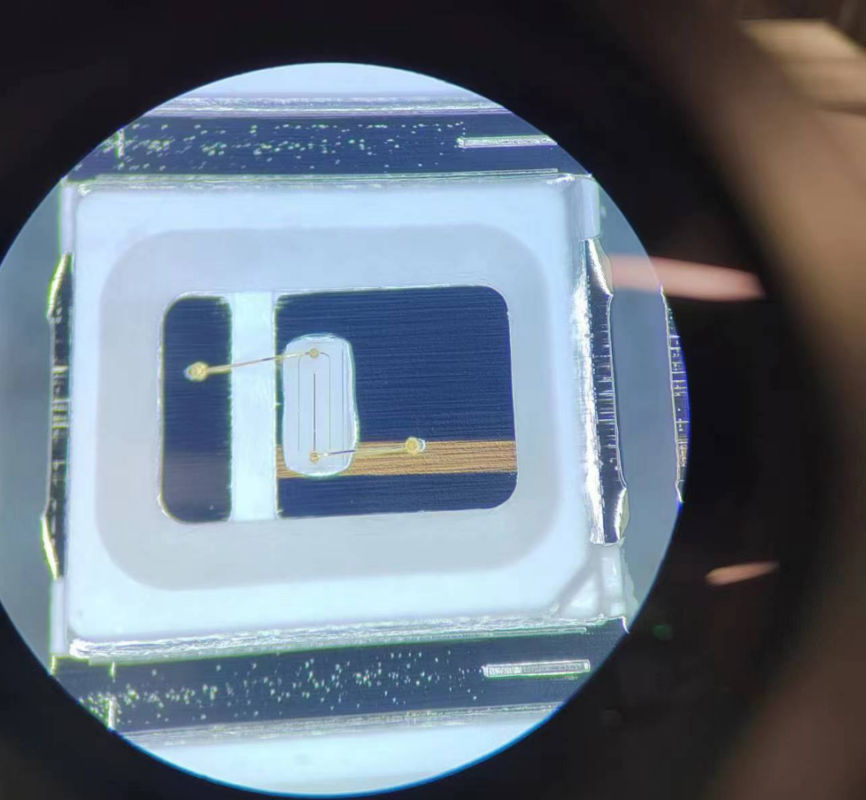

How to identify if the bonding wire of SMD LEDs is made of 99.99% pure gold?

Identifying whether the bonding wire of SMD LED chips is made of 99.99% pure gold may require laboratory testing or other methods of identification. Here are some common methods and indicators:

Establish long-term cooperation agreements with suppliers: Confirm with the LED chip supplier and manufacturer that they use 99.99% pure gold wire as the bonding wire material. The supplier should provide detailed information regarding product specifications and materials used, ensuring the use of 99.99% pure gold wire through a cooperative agreement.

Observe the color of the bonding wire: We conduct sample dissolution before storage and carefully observe the surface of the bonding wire using a microscope or magnifying glass. 99.99% pure gold wire typically has a smooth and uniform surface without noticeable impurities or color changes. Although this method has limitations, it can serve as one of the routine production inspection methods.

Conduct chemical analysis: Regularly provide product samples to third-party laboratories for chemical analysis. These laboratories use appropriate analytical techniques, such as mass spectrometry or X-ray fluorescence spectroscopy, to extract and analyze samples of the bonding wire. This allows for accurate determination of the wire’s composition, including the purity of the gold.

Silicone Injection-Moulded IP67

R2R VS S2S TECHNOLOGY

SOB IP68 Waterproof LED Strip

On the Color Temperature of LED Strip Light

- [email protected]

- +86-755-29515201

- +86-755-29515205

- 3th Floor,No.1 Building,Shunchengji Industrial Park,Dalang Town,Longhua District, Shenzhen,China

- Copyright ©

- 2025

- Shenzhen Deno Lighting Electronic Co., Ltd