What is Dim to Warm LED Flexible Strip Light?

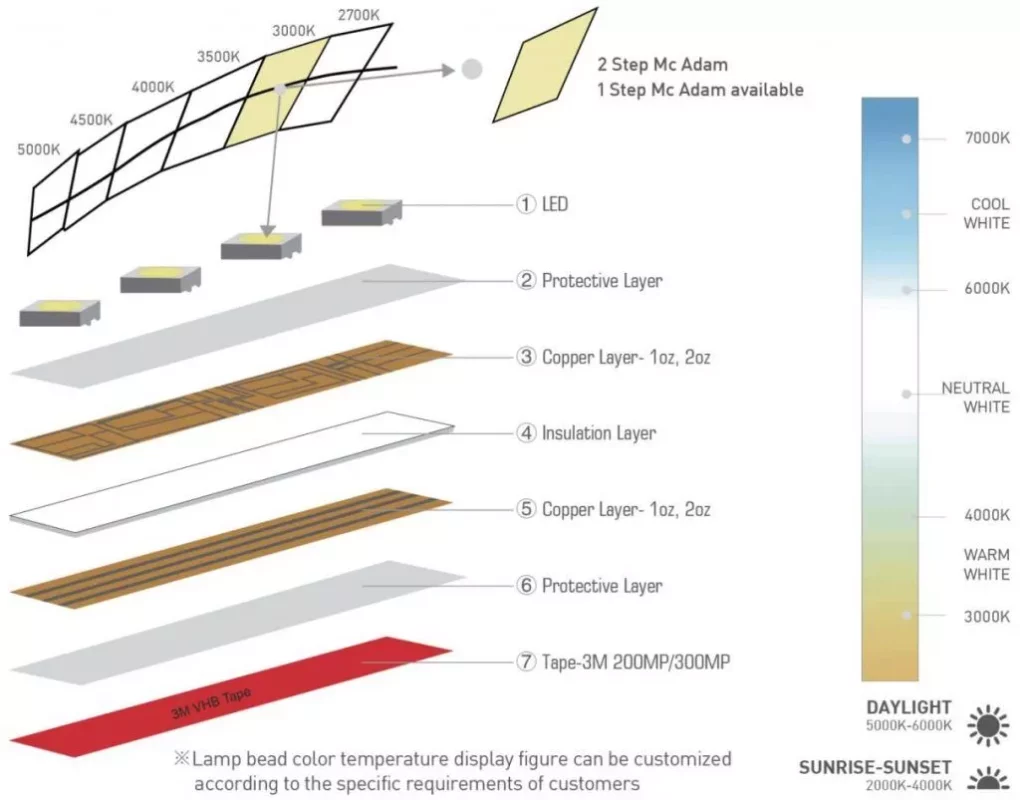

The Dim to Warm LED flexible strip light utilizes the principle of PWM dimming, incorporating a unique dual-color temperature LED circuit design. During the PWM dimming process, it automatically transitions from cool white to warm white, creating a soft and comfortable lighting ambiance. This “dim to warm” characteristic is the core highlight of the Dim to Warm LED strip light.

Product Features

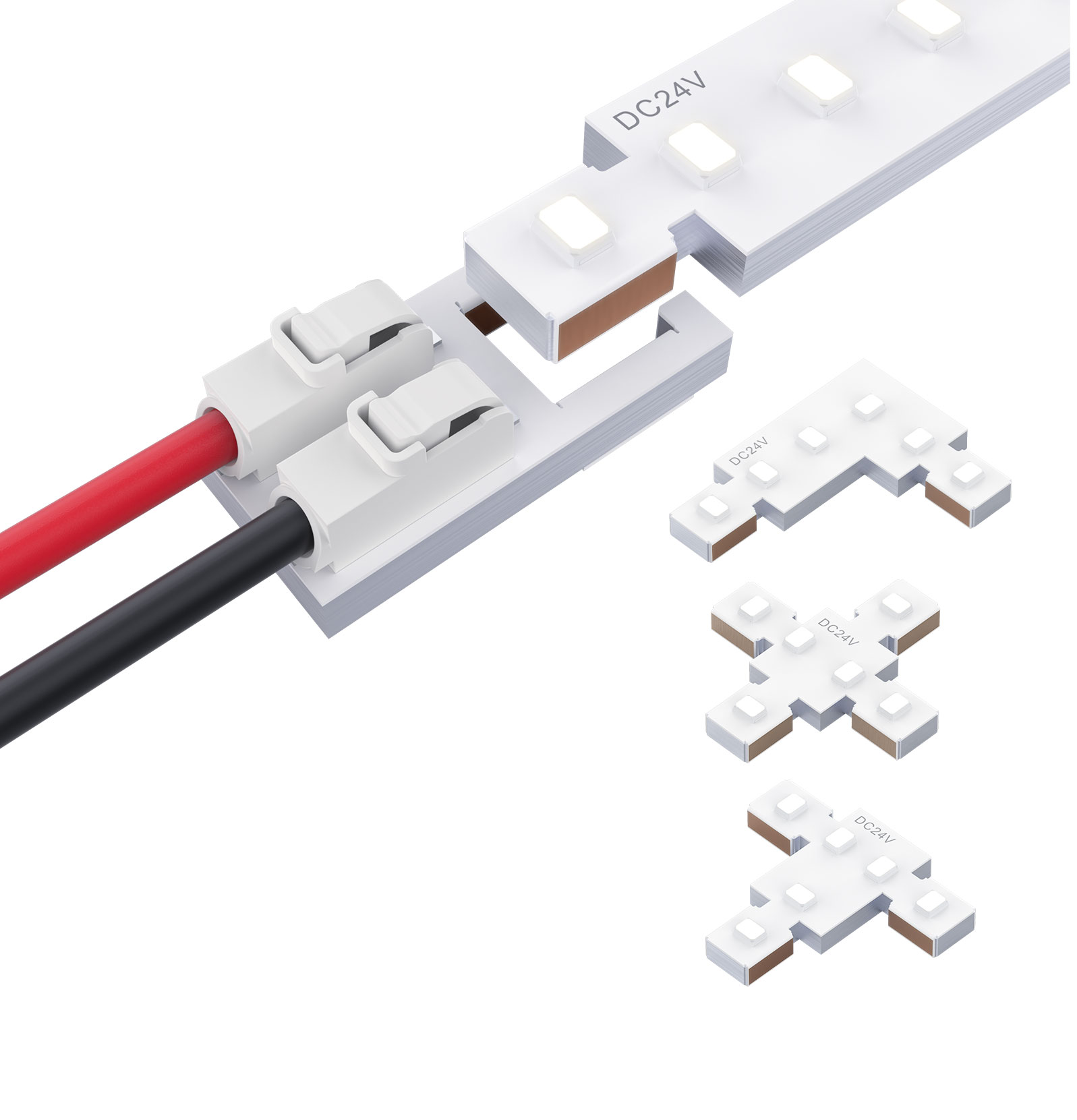

1. Utilizes 1800K warm white and 4000K cool white LED chips, arranged in an alternating pattern.

2. Automatically transitions the color temperature from 3000K to 1800K as the light is dimmed, achieving a gentle and comfortable lighting effect.

3. Supports seamless dimming from 100% to around 1% brightness.

4. Lower brightness results in lower color temperature, creating a “dim to warm” effect.

5. Flexible strip design for easy installation and layout.

6. Employs high CRI LEDs, available in CRI>90, CRI>95, or even full spectrum (2835 series only), for superior color rendering…

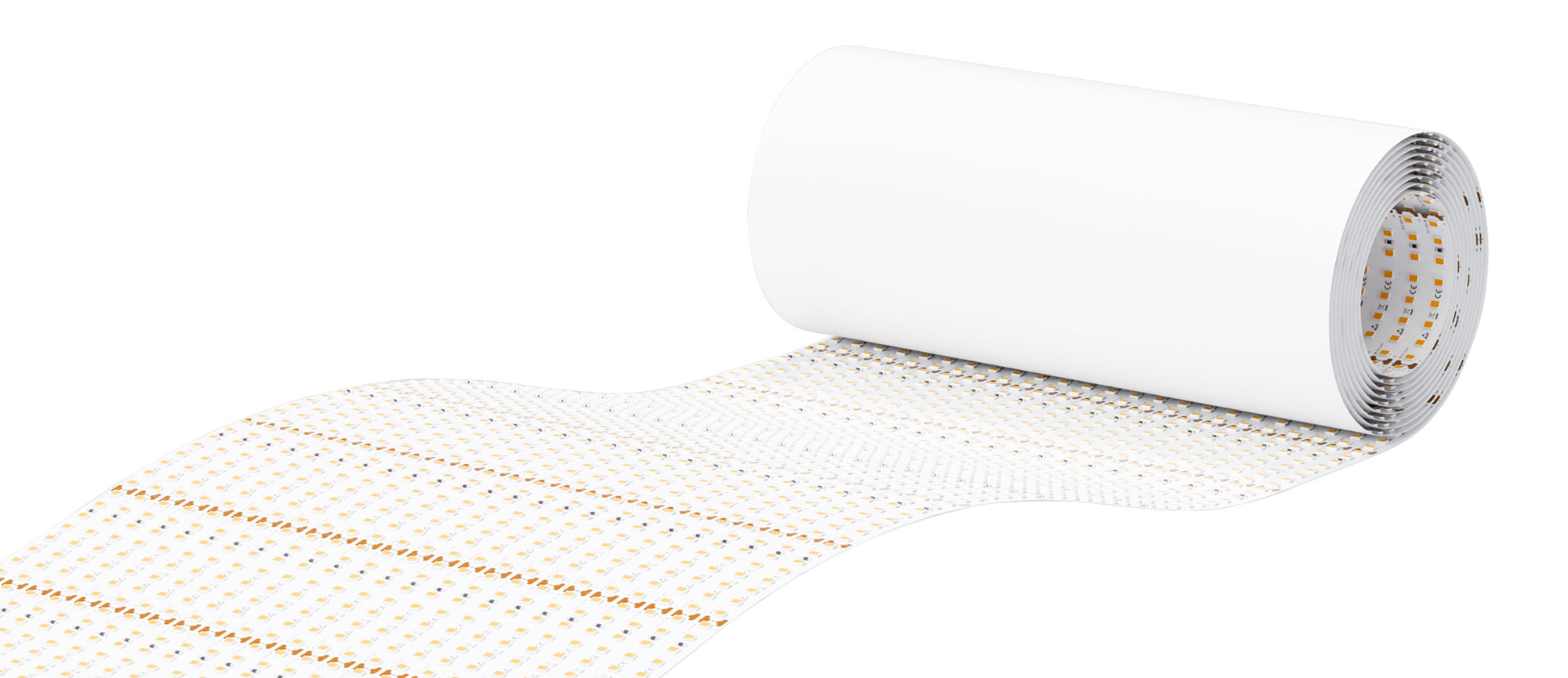

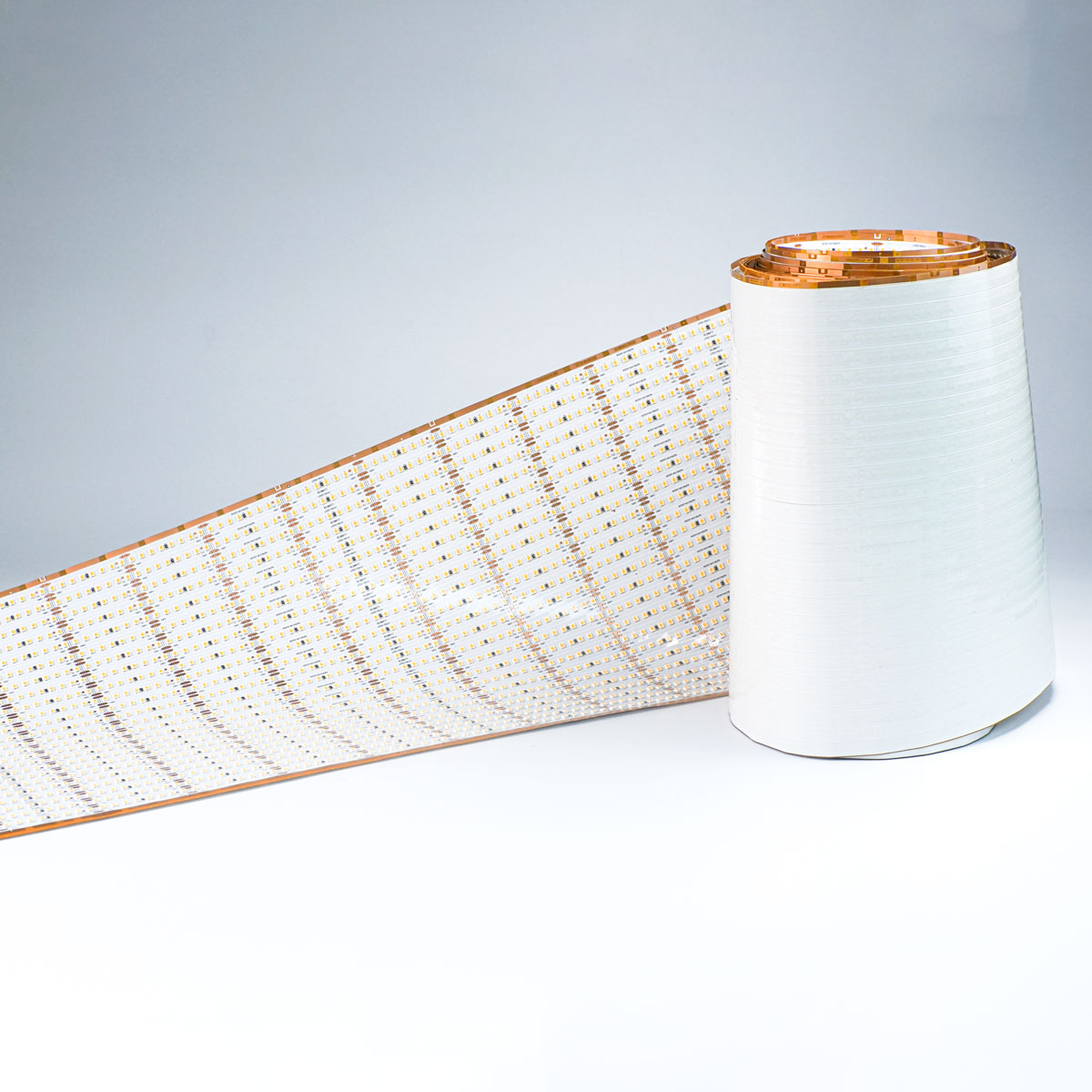

– 2835 SMD LEDs Dim to Warm LED strip: 168 LEDs total, with 84 pcs of 1800K and 84 pcs of 4000K.

– 2216 SMD LEDs Dim to Warm LED strip: 224 LEDs total, with 112 pcs of 1800K and 112 pcs of 4000K.

– High-density Dim to Warm LED strip: 420 LEDs total, with 210 pcs of 1800K and 210 pcs of 4000K.

– SOB (COB pro) process Dim to Warm LED strip: 420 LEDs total, with 210 pcs of 1800K and 210 pcs of 4000K, ensuring no pixelation.

Quality system And Reliability test

As an LED linear lighting manufacturer, we value the optimization of our quality management system and reliability testing procedures to ensure customer satisfaction with the product quality.

1. Define Quality Objectives and Standards:

Firstly, it is crucial to clearly define the quality objectives and standards for LED linear lighting products. This includes specifying product specifications, performance requirements, reliability indicators, as well as relevant industry standards and regulatory requirements. Establishing clear objectives and standards will serve as the foundation for our quality management system, guiding our work.

2. Design and Plan Quality Processes:

When designing and planning quality processes, we need to consider all stages of production and testing comprehensively. This encompasses aspects such as raw material procurement and inspection, process control, product testing and validation, as well as packaging and shipping of the final products. Each stage should have appropriate quality control measures and records in place to ensure effective quality control.

Delivering Excellence in Fblexible LED Light Strip Manufacturing: A Comprehensive Overview of Our Production Process and Quality Assurance

By addressing these aspects, we will be able to comprehensively showcase our strengths and professionalism in LED light strip production to our customers. Our focus on material selection and procurement, well-designed production flow, advanced manufacturing techniques, stringent quality control systems, traceability, and customization capabilities are all key factors that ensure the quality and performance of our LED light strip products. We look forward to sharing more detailed information about our production process and demonstrating how we can meet your requirements and deliver excellent LED light strip products.

1. Material Selection and Procurement Process: DENO emphasizes the selection and procurement of key materials in LED light strip manufacturing, particularly high-quality LED chips, flexible printed circuit boards (FPC), and other components. We have established long-term partnerships with reliable suppliers and implemented stringent evaluation and selection processes to ensure that the materials we use meet the required quality standards and certifications.

2. Overview of the Production Process: DENO’s LED light strip production process covers everything from material preparation to final assembly and packaging. Our production flow is carefully designed and optimized to ensure efficient and consistent production of DENO’s products.

Our Latest Articles

Silicone Injection-Moulded IP67

R2R VS S2S TECHNOLOGY

SOB IP68 Waterproof LED Strip

The Selection and Application of Color Temperature Lighting

Why DENO

We will do strict

3 Professional laboratories

Using the top grade material

14 years of factory

How to deliver specialized LED linear lighting?

Send Your Detailed Enquiry

Please provide us with more information about your requirements, including dimensions, quantity, and materials, so that we can accurately assess and assist you.

Product Design

You can send samples or product drawings. Even if you only have basic ideas, you can share them with us. We will collectively review and confirm the design and drawings you require.

Pilot Production With Samples

Validate the feasibility of the product design, assess the effectiveness of production processes, and conduct performance testing of the product.

Ensure Timely Delivery of Mass Production

We take care of the production phase and here is our promise: the right materials, the right quantity, the right printing, at the right time.