Silicone Injection-Moulded IP67

At Denolighting, we are committed to continuous refinement of product details. This update focuses on the development and evolution of our injection-moulded edgeless end cap technology. Through ongoing improvements in materials, structure, and manufacturing processes, we have optimized product appearance, protection performance, and compatibility across multiple installation systems.

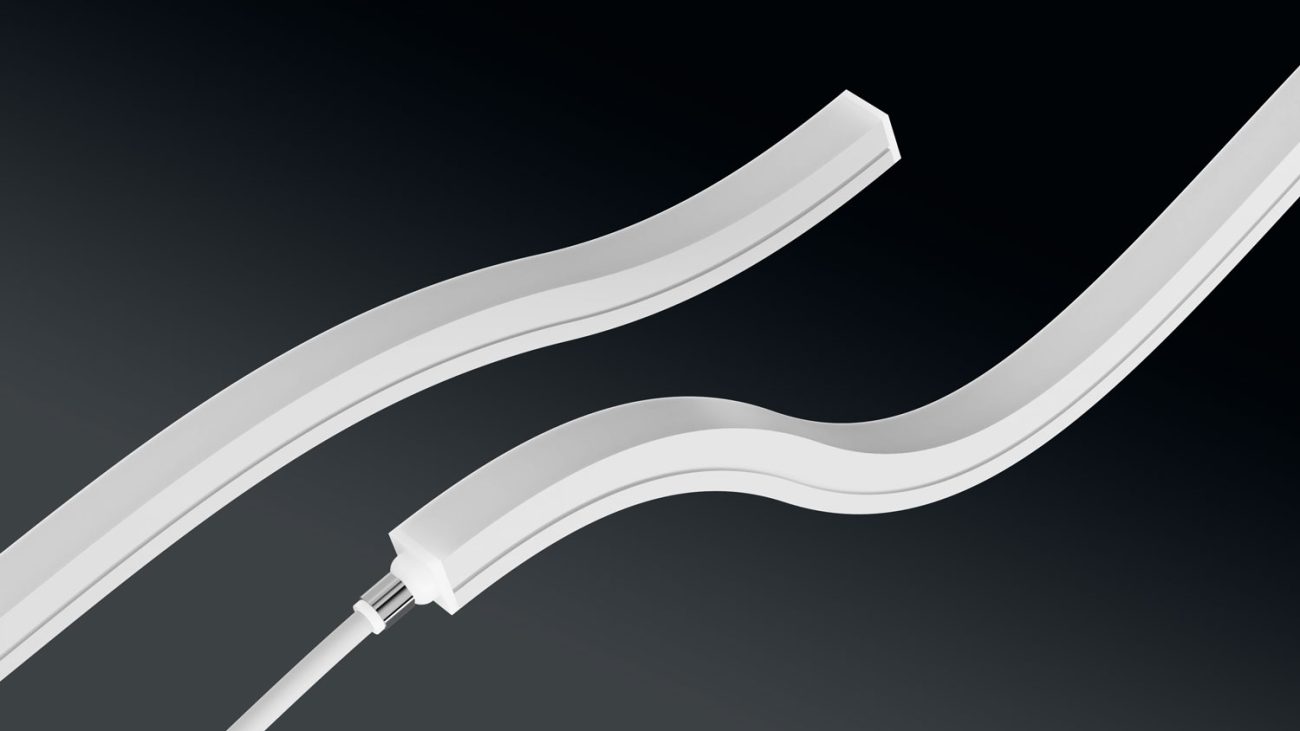

The edgeless end cap not only enhances waterproof performance and overall aesthetics but also ensures smooth light transition at the strip ends after connection — with no bulging or visual disruption. Especially when integrated with aluminum profiles, it solves common issues like lifting or misalignment found in traditional end caps, significantly improving installation efficiency and engineering quality.

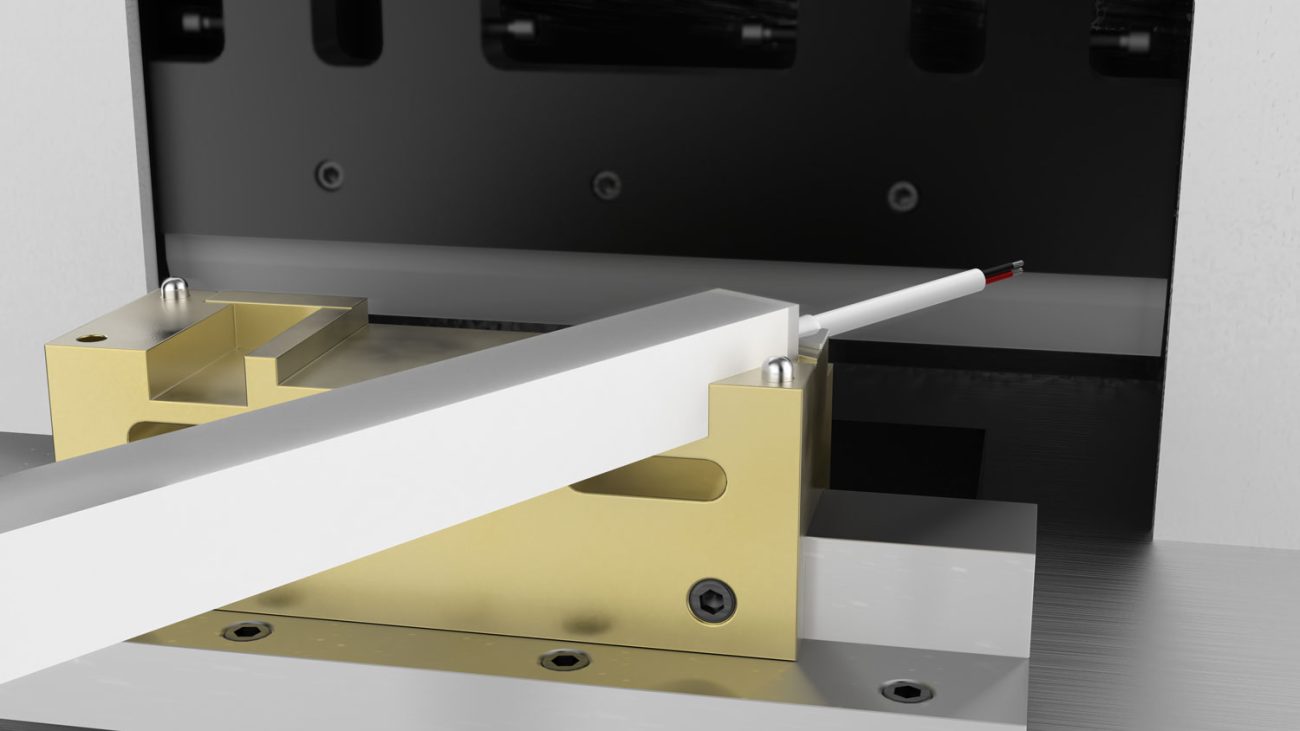

Injection molding through dies ensures structural consistency and mass production efficiency

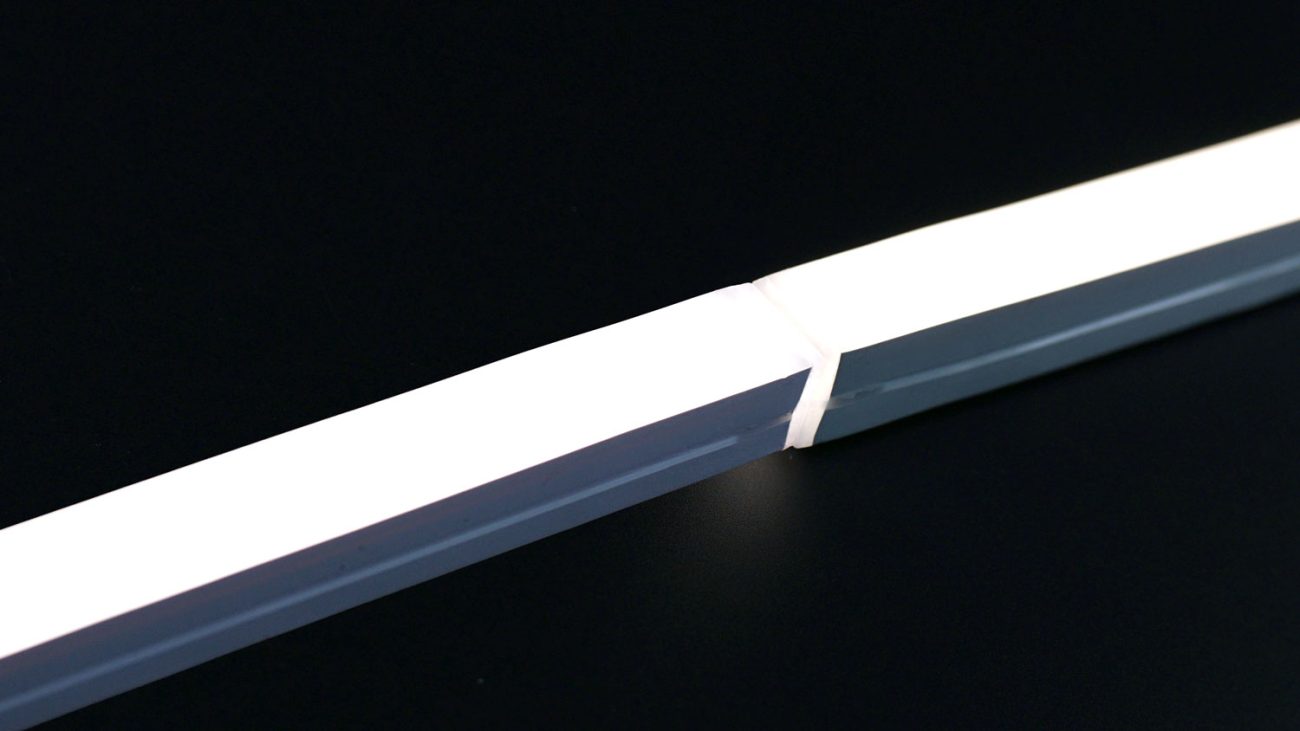

Seamless:No opaque plugs at joints; light flows seamlessly to prevent interruptions.

Sleek and Durable : A metal compression ring secures the cable exit, achieving Ip67 waterproofing and a cleaner, more consistent finish.

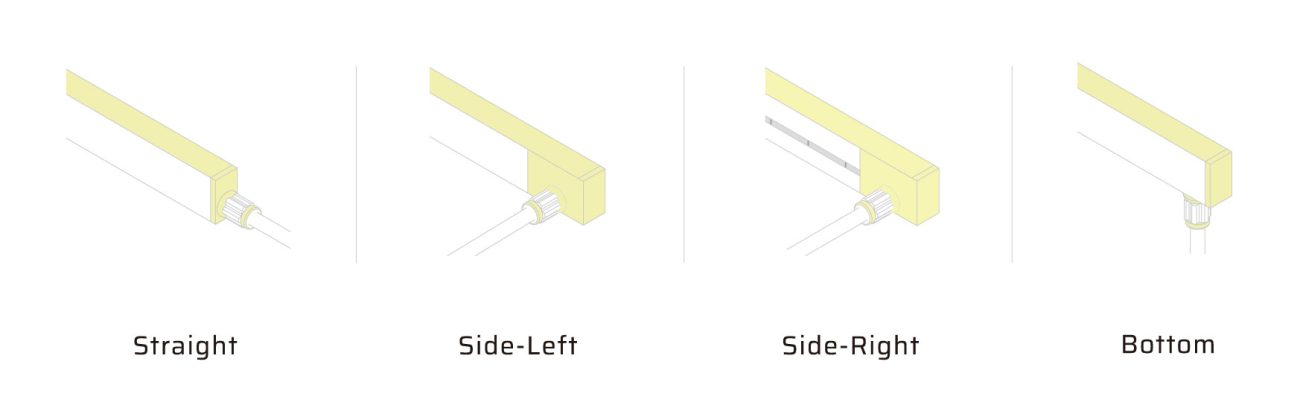

Cable direction

The edgeless injection-moulded end cap is well-suited for a variety of lighting applications, including architectural outlines, landscape illumination, commercial facades, and signage systems. With outstanding waterproof performance, installation compatibility, and seamless light continuity, it is the ideal choice for high-spec lighting projects in demanding environments.

Silicone Injection-Moulded IP67

R2R VS S2S TECHNOLOGY

SOB IP68 Waterproof LED Strip

On the Color Temperature of LED Strip Light

- [email protected]

- +86-755-29515201

- +86-755-29515205

- 3th Floor,No.1 Building,Shunchengji Industrial Park,Dalang Town,Longhua District, Shenzhen,China

- Copyright ©

- 2025

- Shenzhen Deno Lighting Electronic Co., Ltd