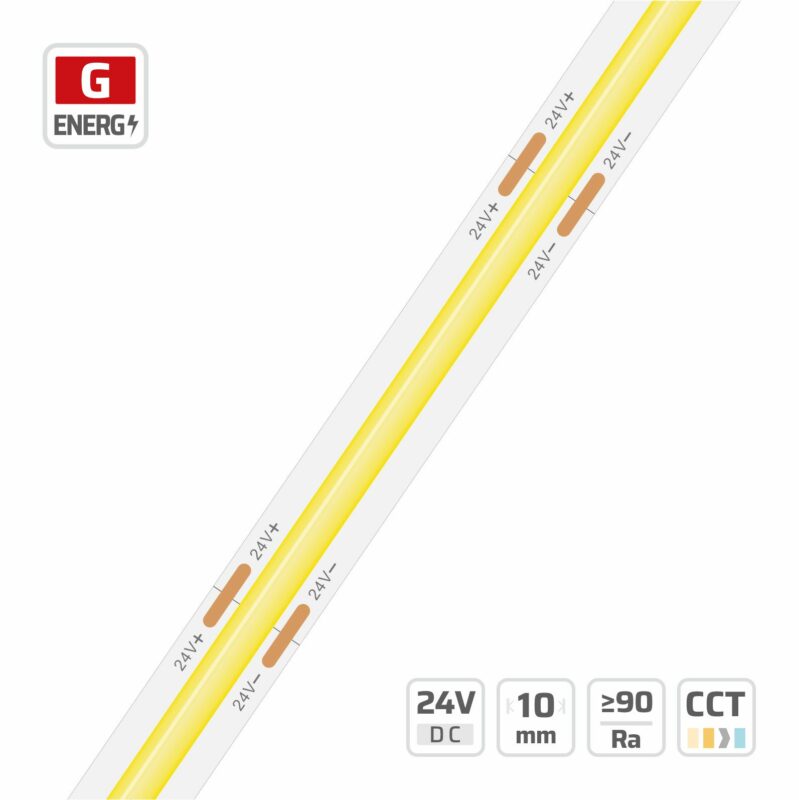

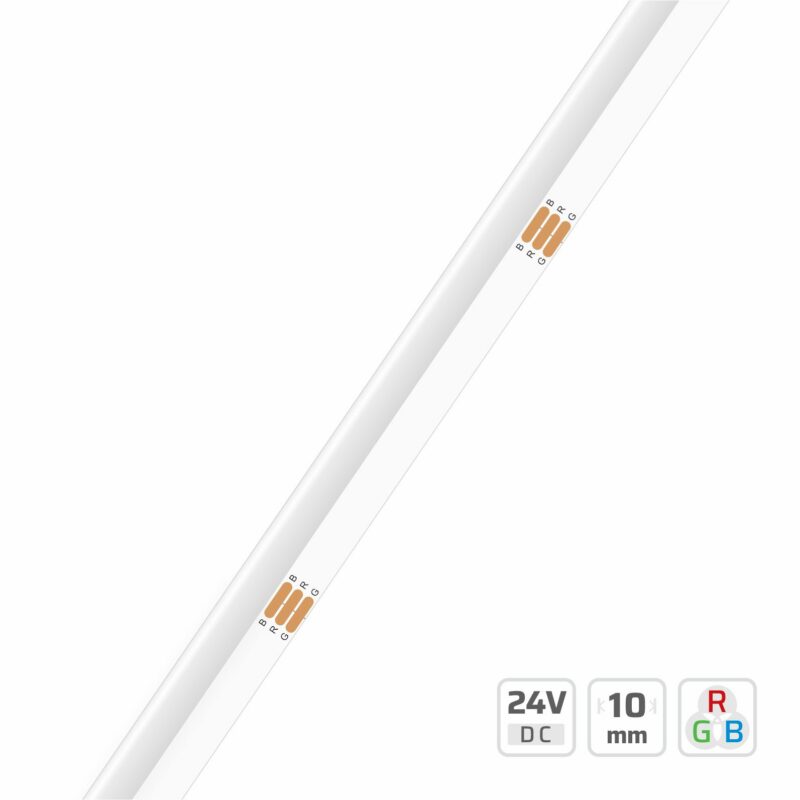

COB Series

Product Category

Need help? Contact us for more expert support on light strips!

COB LED strip lights (Chip-on-Board LED strip lights) are a popular type of LED strip light currently on the market. Their characteristics, advantages, and disadvantages are as follows:

Characteristics:

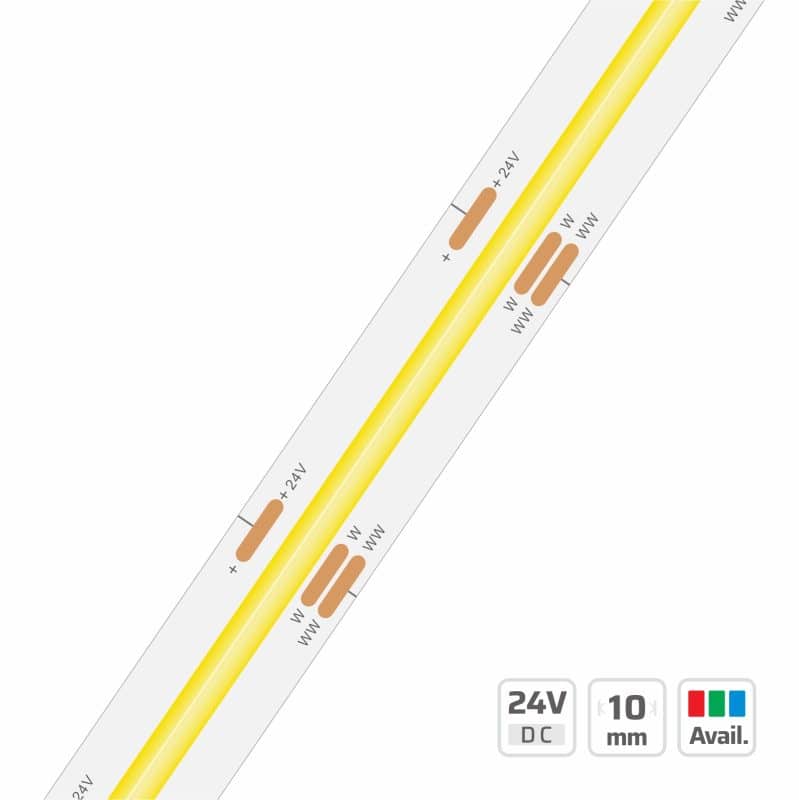

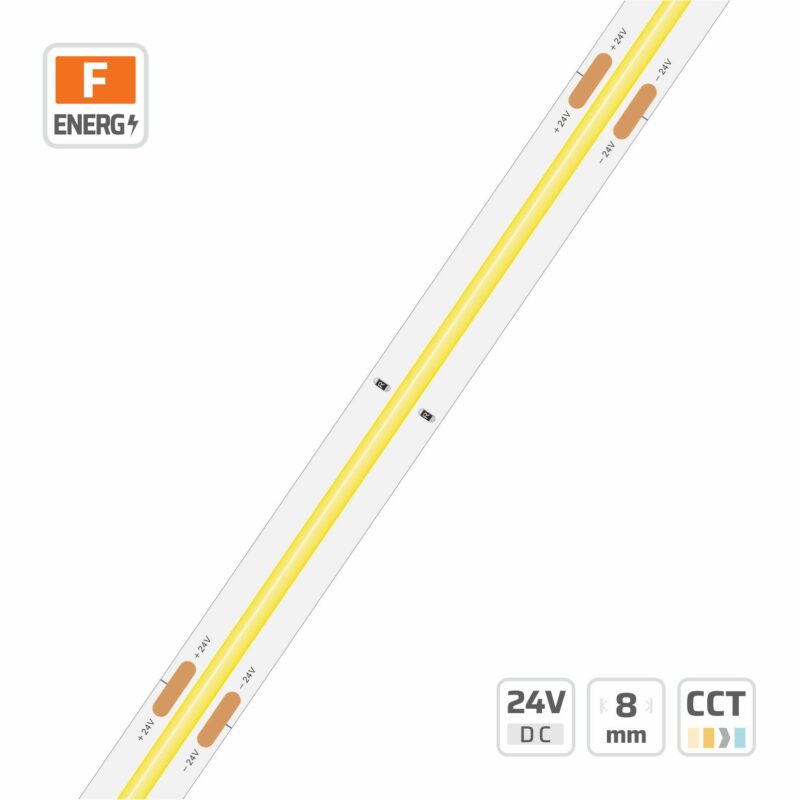

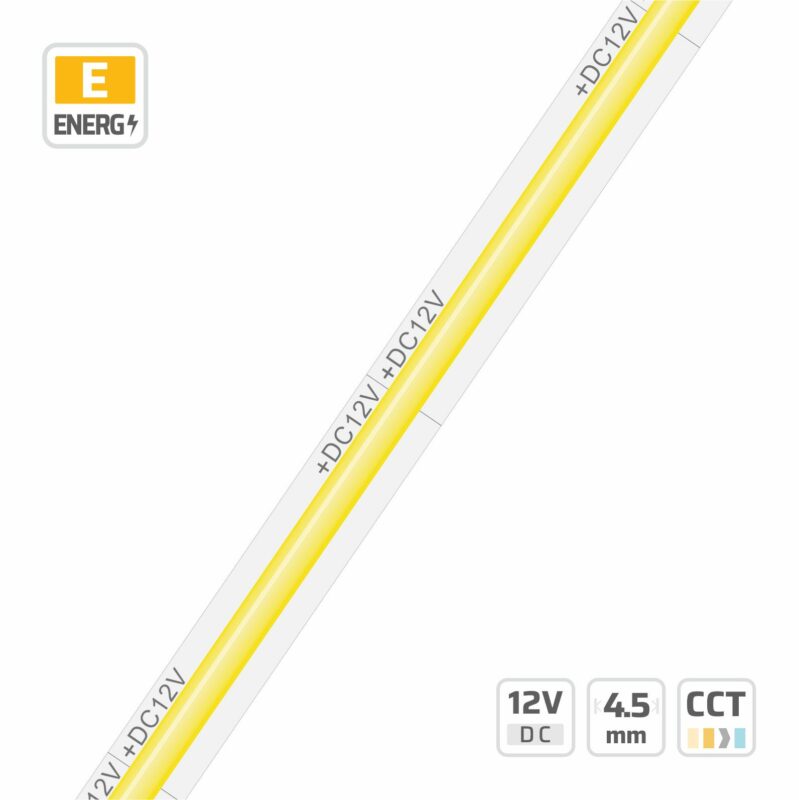

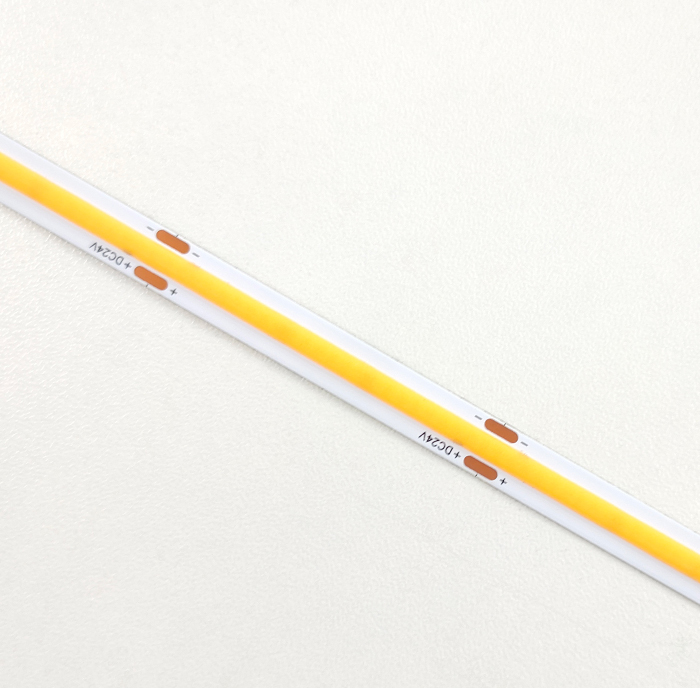

- COB Technology Application: Utilizes COB technology, where LED chips are directly mounted on the circuit board of the strip, forming an integrated light source.

- High Integration: The COB design enables a high level of integration, allowing the LED chips to provide linear illumination in a limited space.

- Encapsulation Structure: Typically, a layer of phosphor gel is applied over the LED chips to adjust and produce different color temperatures of white light.

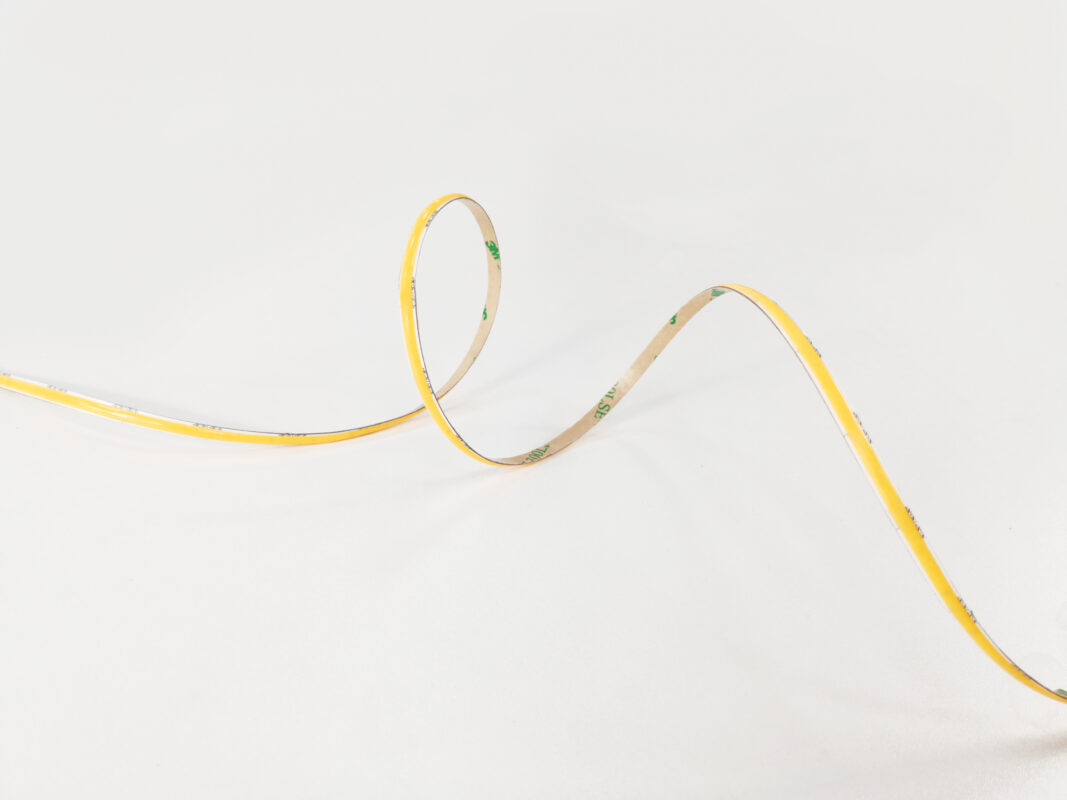

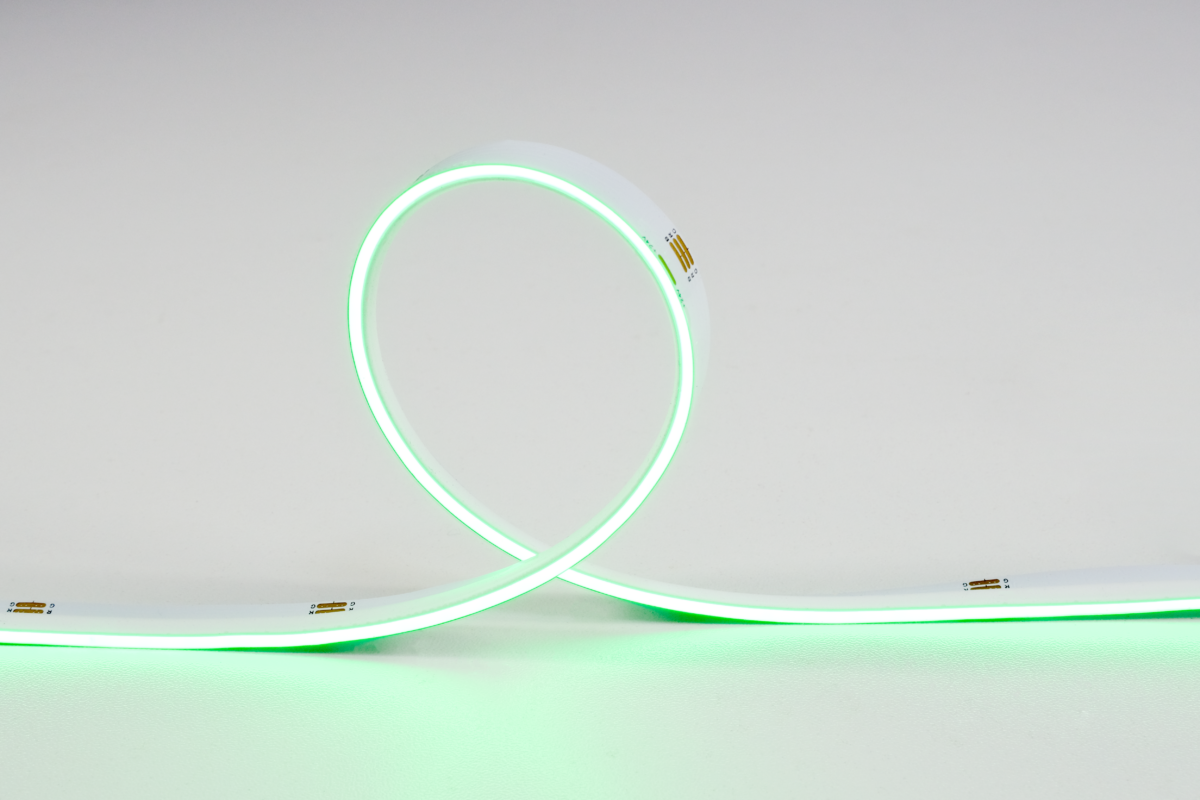

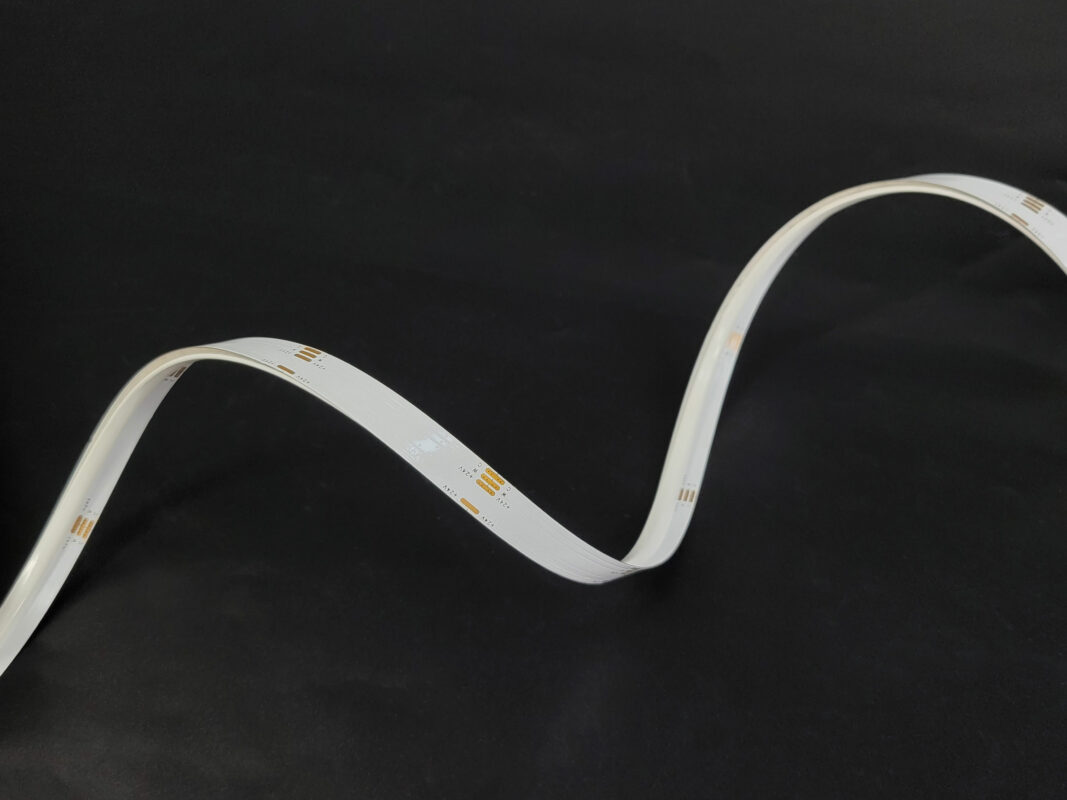

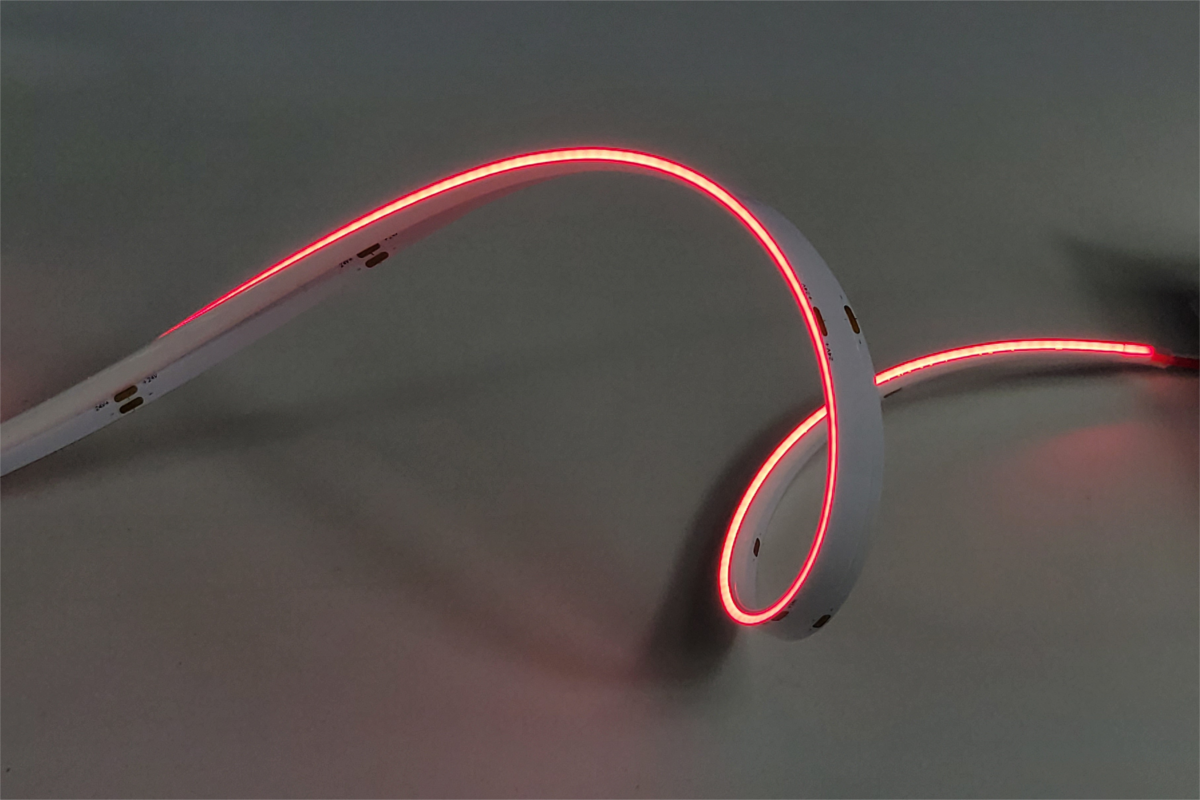

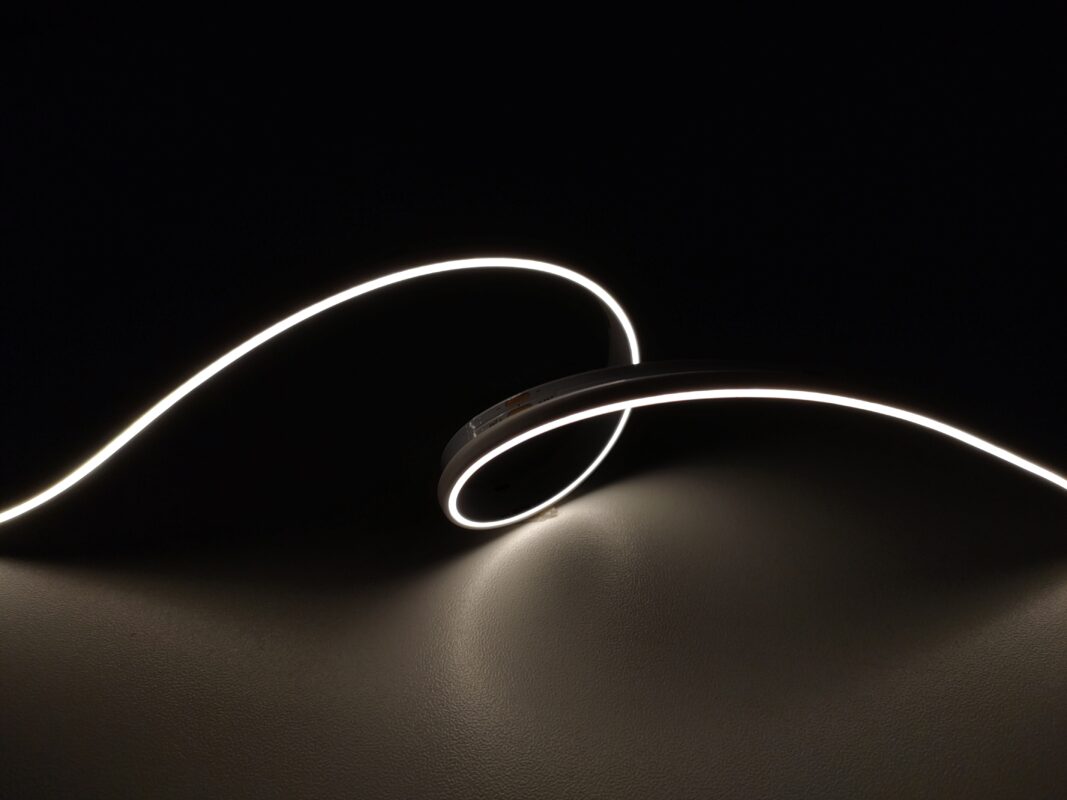

- Flexible FPC Board: Commonly uses flexible FPC (Flexible Printed Circuit) as the substrate, offering high flexibility suitable for curved and contoured applications.

Advantages:

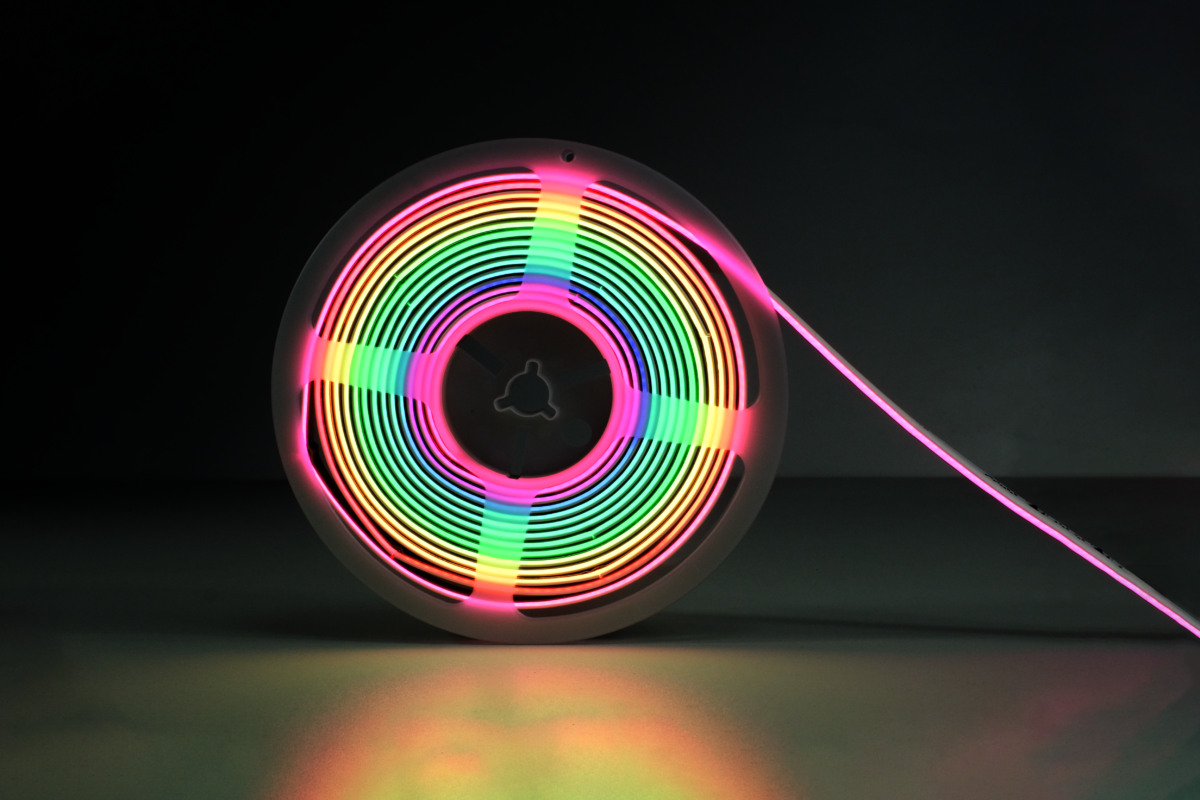

- Uniform Linear Light: Due to the integration and uniformity of LED chips, COB LED strips usually provide more uniform light distribution.

- Energy Efficiency: Compared to traditional light sources, COB LED strips have a higher efficiency ratio.

- High Reliability: The high integration and advanced technology improve the overall reliability and stability of the product.

- Design Flexibility: The flexible FPC board allows the strips to be used in various curved and special-shaped installation scenarios.

- Lower Cost: Compared to traditional LED strips or SOB LED strips, COB LED strips eliminate the LED packaging and binning processes, directly mounting the light-emitting chips on the FPC. This reduces overall costs and makes COB LED strips more cost-effective, appealing to the market. However, due to the thin FPC requirement, COB LED strips typically have a power limit of around 12W/m to avoid damaging the light-emitting chips during bending.

Disadvantages:

- High Heat Dissipation Requirements: Since the chips are directly mounted on the FPC without corresponding heat dissipation brackets, COB LED strips require good heat dissipation design to ensure long-term stable operation. Hence, the power of COB LED strips is generally controlled at 12W/m as a limit.

- Color Consistency: Since the light-emitting chips are first mounted on the FPC and then coated with phosphor gel, color consistency can only be ensured within the same batch of products. Different batches may have slight color variations, which may not meet strict color consistency requirements.

- Limited to Linear Design: Due to the direct integration of chips on the circuit board, COB LED strips may not be suitable for certain nonlinear design or special-shaped applications.

Overall, COB LED strips are becoming increasingly popular in indoor lighting and decorative lighting markets due to their uniform brightness, light distribution, and design flexibility. They are particularly suitable for applications requiring uniform linear light.